With the Liebherr Autonomous Operations system, Liebherr-Werk Bischofshofen GmbH has achieved an important milestone in the digitalisation of wheel loader operations. Several test machines are now being trialled at customers’ sites in various application scenarios – from industrial environments and mixing plants to challenging environments such as gravel pits and quarries. The knowledge gained from these tests will help to further customise the technology to meet user requirements.

“At bauma 2025, we showed more than just a technological vision, namely a system that will offer our customers clear added value in their day-to-day work. We are continuing to develop in this direction – together with our test customers,” explained Dr Manuel Bös, head of emerging technologies at Liebherr-Werk Bischofshofen GmbH.

The Liebherr Autonomous Operations is particularly suitable for monotonous, repetitive tasks, like feeding hoppers or loading material from A to B. This will free up employees and enable them to accomplish more varied and complex activities – tasks that require human experience and decision-making skills.

The autonomous system can also be adopted for works in hazardous areas, e.g. in areas of a quarry where there is a risk of collapse, safely and without a driver. This reduces the workload for employees and increases safety on the construction site at the same time. “The feedback from our test customers shows that the system opens up new possibilities in work organisation,” said Mr Bös.

Intuitive, user-friendly operation

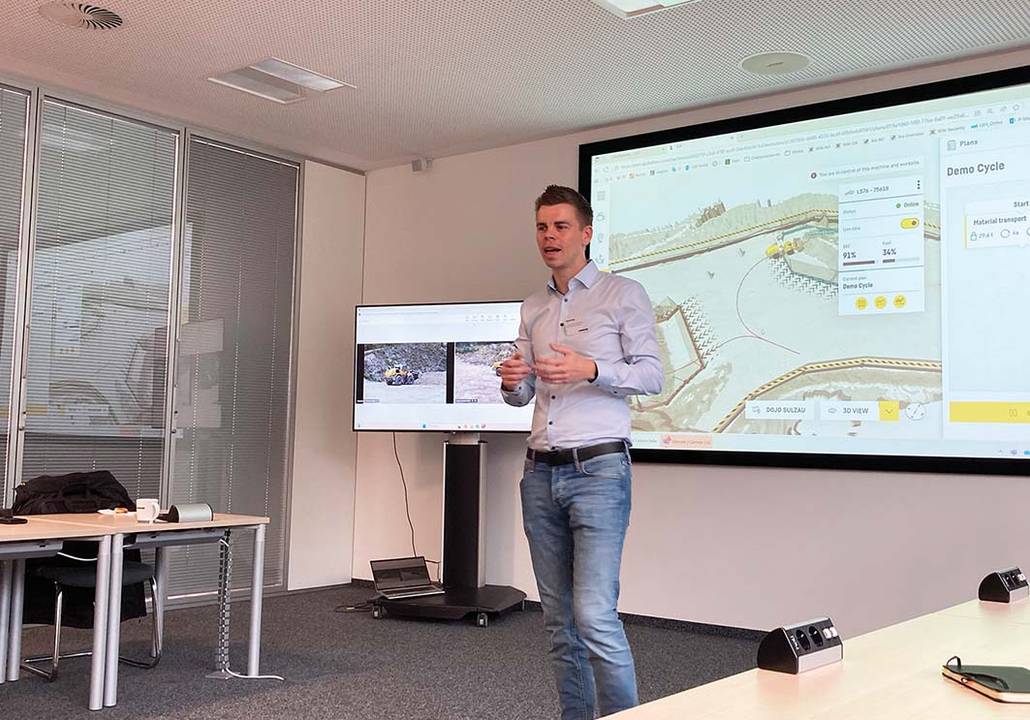

Job planning is carried out using the Autonomous Job Planner web application developed by Liebherr. Work orders can be defined easily and graphically in a 3D operating environment without any special IT knowledge. The machine recognises its surroundings, piles and obstacles thanks to 3D environmental sensors, and there’s no need for additional aids such as drones or separate surveying technology.

On that basis, the machine plans the individual work cycle, executes it independently and adapts to changes in the environment and different bulk materials fully automatically. The system does not require GPS, which means it can also be used in halls, underground, on high demolition walls or under vegetation.

The autonomous wheel loader runs with constant performance and efficiency while allowing time-independent and flexible material transport, resulting in better planning and higher productivity. Plus, the machine’s gentle operation helps minimise wear. “The machine works efficiently, proactively and conserves resources. This reduces operating costs and increases the service life of the components,” said Mr Bös.

In addition, users can switch seamlessly between classic, manual cabin operation or fully autonomous operation. For small and medium-sized companies in particular, the autonomous driving system offer new opportunities in the organisation of working hours and the targeted deployment of employees – and thus makes an important contribution to the digital transformation of the industry.